Induction Heating Equipment

TESI designs and manufacturing best in class induction heating equipment for the pipeline construction industry. The company has worked on major onshore, offshore and

A. Induction Heating Coil:

The Induction Heating Coils are designed to heat the pipe after welding in order to prepare the pipe cutback surface for coating.

The positioning of the windings is precisely studied to provide uniform heating or a customized temperature distribution on the pipe joint surface, while the silicon sheath on the windings ensures good resistance to high temperatures.

Induction heating coils can be customized according to given technical requirements.

B. Induction Heating Generator:

Induction heating self powered generators (DIESEL): IHG series

• Self contained skid-mounted unit

• 120 kVA to 350Kva high frequency generators

• Diesel powered air cooled engine

• Auxiliary power sourced

• Electronic specifications display

• Remote controlled

C. Induction heating electric motor generators (CONVERTERS):

CHG series:

Available Model: CHG 80 CHG 110 CHG 180 CHG 350

Max Output Power: 80 kW to 350

D. Induction heating STATIC generators (INVERTERS):

SHG series:

Available Model: SHG 40 SHG 80 SHG 120 SHG 240 SHG 320.

Max Output Power : 40 kW to 320

E. Fusion Bonded Epoxy (FBE)

F. Field Joint Coating Equipment

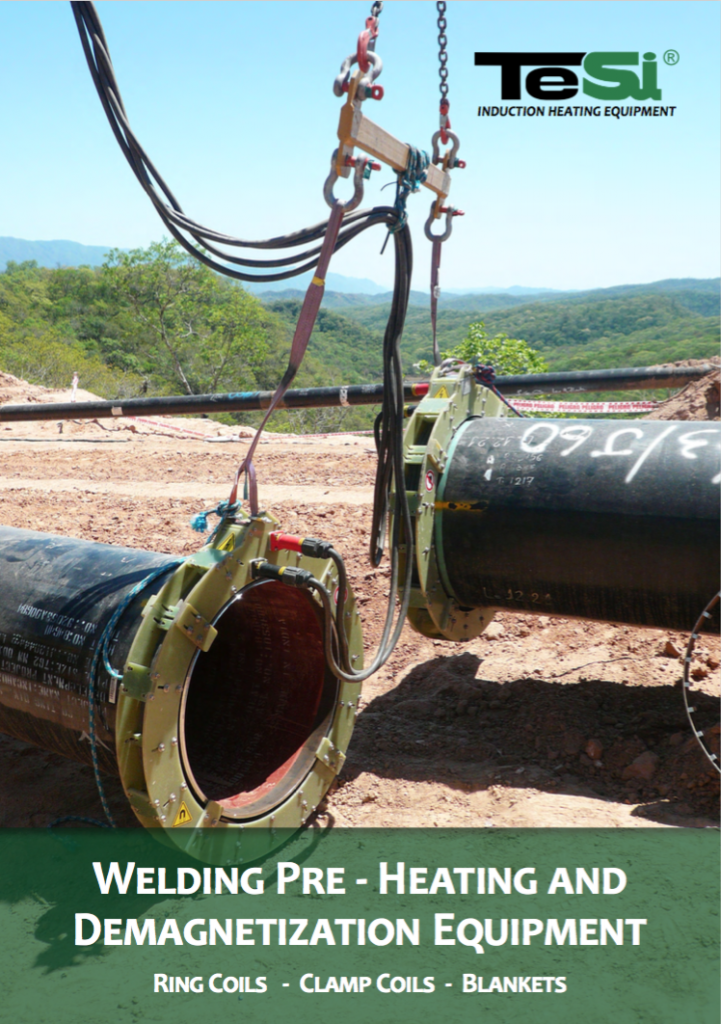

G. Welding Pre-Heating & Post Weld Heating Equipment.

H. Automatic Sand Blasting Equipment for Pipeline .